As logistics competition intensifies, 30% of transportation costs stem from inefficient fleet management (Berg Insight, 2024). With the commercial fleet management market set to hit $42B by 2027, GPS tracking is the core driver. This report decodes how to select GPS solutions for cost reduction, compliance, and competitive advantage.

1. Core Value & Industry Pain Points

Key Benefits:

15-25% fuel savings via route optimization (U.S. DOT)

20%+ asset utilization through real-time dispatch

35% accident reduction with driver behavior monitoring (FMCSA)

95%+ on-time delivery with precise ETAs

Critical Pain Points:

Hidden costs (idling, detours, fuel theft)

Asset security risks (theft, unauthorized use)

Compliance pressure (ELD mandates, HOS rules)

Reactive customer service

2. 7 Golden Selection Criteria

1. Precision & Reliability

Multi-constellation support: GPS + GLONASS + Galileo (±1.5m accuracy)

Signal resilience: Metal containers, urban canyons, underground sites

Backup tech: Cellular-assisted GPS (A-GPS)

2. Real-Time Tracking Capabilities

Update frequency: Sub-10-second refresh (vs. 1-5 min basic trackers)

Data compression: 50%+ data savings (e.g., CAN bus integration)

Offline caching: Stores 72+ hours of data during signal loss

Case Study: Maersk reduced incident response time by 80% with real-time tracking.

3.Battery Life & Durability

Power options: Hardwired (OBD-II) or 3+ year wireless battery

IP68/IP69K rating: Dust/waterproof for harsh environments

Anti-tamper tech: Geofence alerts + motion-triggered alarms

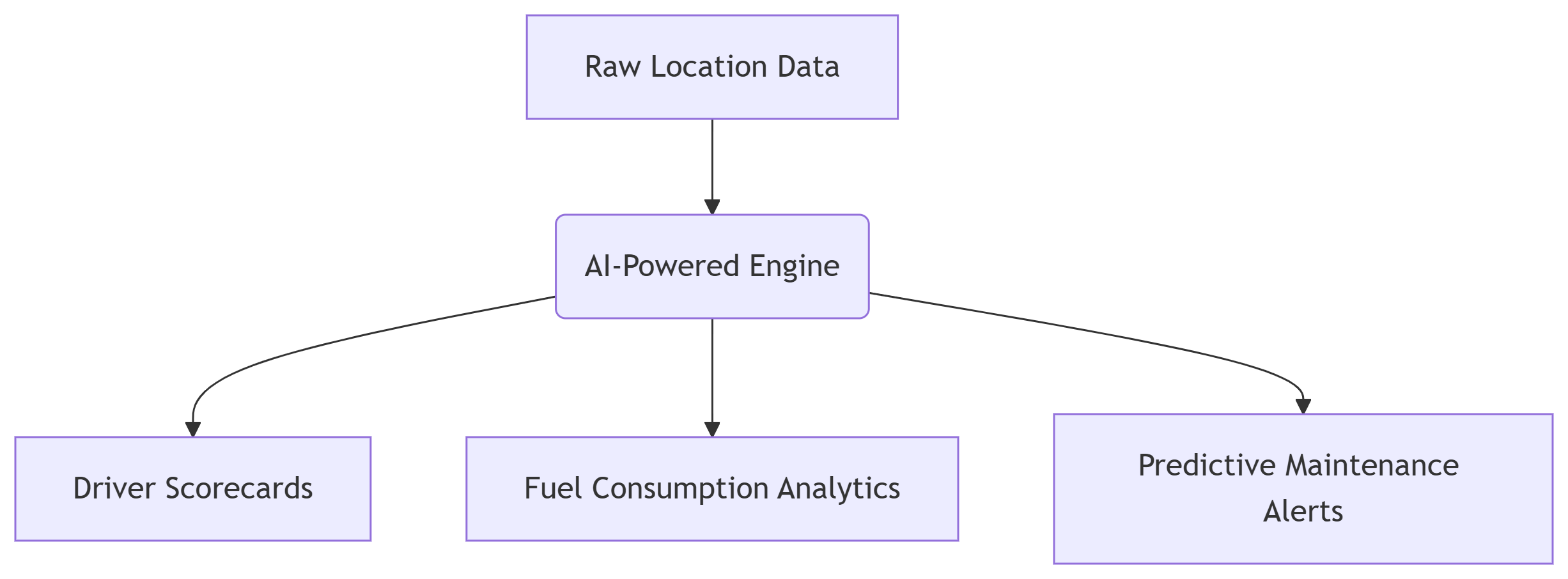

4. Intelligent Analytics Platform

Advanced features:

AI-powered idle time reduction

Carbon footprint calculators

Automated ELD logs

5. Compliance & Security

ELD compliance: FMCSA/HOS/DSM regulations

Safety suite:

Collision detection (G-sensor)

SOS panic buttons

Driver ID authentication

6. Integration Scalability

Sensor compatibility:

Temperature/humidity (cold chain)

Door open/close sensors

Cargo weight monitors

API ecosystem: TMS/ERP integration (SAP, Oracle, MercuryGate)

7. Cost Structure & ROI

Cost Type Entry-Level Premium

Hardware $50-$100/unit $150-$300/unit

Monthly Service $10-$20/unit $25-$40/unit

ROI Calculation (20-vehicle fleet):

Costs Savings

$14,400/year Fuel: $7,200

Maintenance: $2,500

Accident Reduction: $9,000

Net Annual Gain: $18,700+

Payback Period: <10 months

3. Future Tech Trends

5G + Edge Computing: Sub-second remote control (e.g., engine lock)

Blockchain Auditing: Immutable supply chain records

Autonomous Integration: Sensor fusion for self-driving trucks

ESG Compliance: Real-time emissions tracking

4. Procurement Strategy

Vendor Evaluation Matrix

Criteria Weight Key Checks

Technical Proof 30% Live environment test reports

Industry Cases 25% Same-scale client references

TCO 20% Hidden fees (setup/upgrades)

API Flexibility 15% Pre-built TMS connectors

Support SLA 10% 24/7 multilingual support

Conclusion: Building Your Digital Backbone

Top-tier logistics operators like DHL and UPS treat GPS tracking as a strategic nervous system, not a tool.

To avoid costly mistakes:

Prioritize scalable modular platforms over fixed-function devices

Demand real-world POC testing (not lab demos)

Embed data analytics into operational KPIs

In the age of Logistics 4.0, advanced tracking is the new competitive moat. The right solution transforms visibility into actionable intelligence – turning fleets into profit centers.

"Without granular tracking data, logistics optimization is aviation without instruments – dangerously inefficient."

– McKinsey Supply Chain Practice